- Ichalkaranji, Kolhapur, Maharashtra

- GST NO. : 27AZRPK7585N2Z5

- +91-9766667892, +91-9823292327

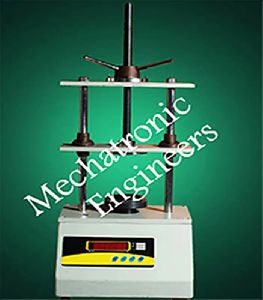

ME-UTE Hydraulic Universal Testing Machine

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Application | Testing |

| Voltage | 440V |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Applications

Mechatronic Engineers make Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted

Accuracy & Calibration

All Mechatronic Engineers make Universal Testing Machines are closely controlled for sensitivity, accuracy, and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS 1828-1975. Mechatronic Engineers Universal Testing Machines Comply with grade “A” of BS: 1610: 1964 and grade 1.0 of IS -1828-1975 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the maximum permissible error is 0.2% of the full reading.

Principle of Operation

The operation of the machine is by hydraulic transmission of load from the test specimen through DIGITAL PRESSURE TRANSDUCER to a separately housed load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on the rupture of test pieces. The load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the DIGITAL PRESSURE TRANSDUCER housed in the control panel. The DIGITAL PRESSURE TRANSDUCER gives a signal to the DIGITAL ELECTRONIC DISPLAY UNIT corresponding to the load exerted by the main ram. Simultaneously the digital Electronic Encoder fitted on the straining unit gives the mechanical displacement to the DIGITAL ELECTRONIC DISPLAY UNIT. Both the signals are processed by Microprocessor and LOAD and DISPLACEMENT is displayed on the to DIGITAL ELECTRONIC DISPLAY UNIT Machine consists of

Machine consists of

Straining Unit

This consists of a hydraulic cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured by revealing the cylinder and ram of any possible side loading by the provision of ball seating. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads, Compression, transverse, bending, shear, and hardness tests are conducted between the lower crosshead and the table. The lower cross-head can be raised or lowered rapidly by operating the screwed columns thus facilitating ease of fixing of the test specimen.

Control Panel

The Control Panel consists of a power pack complete with drive motor and an oil tank, control valves with to DIGITAL ELECTRONIC DISPLAY UNIT. A pressure transducer is connected for load indicator and a rotary encoder for elongation with a resolution of 0.1 mm, is provided to measure the deformation of the specimen

Power Pack

The power pack generates the maximum pressure of 200 kgf/cm2 the hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth.

Hydraulic Controls

Hand operates wheels are used to control the flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable incorporated in the hydraulic system is a regulating valve which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken.

Load Deflection Indicator

It is a microprocessor-based electronic control panel connected with a machine using a Pressure Transducer, Rotary Encoder, and Electronic Extensometer. Using the RS-232 serial communication port our s/w communicates with the machine and gets real-time Load, Deflection, and Extension, and shows on the computer. Electronic digital displays Load Elongation and extension. Facility to hold peak – load and tare facility to make load zero. Elongation display can be set to zero. Optional printer facility. All other facilities maintained under Model UTN. Printer and PC interface.

Electronic Extensometer

Mechatronic Engineers offers electronic extensometer ME-EE-2 to measure material extension with a resolution of one micron. Strain gauge type extensometer to be used up to the elastic limit to determine important parameters like 0.1%, 0.2% proof stress, and Young’s Modulus.

Technical Data

- Gauge Length 25 mm & 50 mm

- Maximum Extension 2 mm

- Resolution 1 micron

- Specimen Diameter 0.5 to 30 mm

- Specimen Thickness up to 30 mm

- Specimen Width up to 30 mm

SPECIAL OPTIONAL ACCESSORIES:

- Load Stabilizer

- Brinell Test Attachment

- Bend Test Attachment

- Shear Test Attachment

- Wide range accessories offered on request at additional cost.

INSTALLATION:

It is recommended that machines be erected on a foundation. Details on the foundation can be given on request

Software Features – Universal / Tensile Testing Machine

Test you can conduct tests…

- Tensile Test

- Compression Test

- Bend Test

- Single Shear

- Double Shear

- Proof Test [Stress Vs %Strain (If Extensometer is used)]

Real-time Graphs

- Dual Graph – Stress Vs %Strain and Load Vs Displacement (If Extensometer is used)

- Load Vs Displacement

Specimen Types

- Round

- Flat

- Hollow

- TOR / TMT Steel

Some Data Entry Points

- Pre – Load Data Entry to avoid slippage in the graph

- Fully customized data entry

- Extensometer Gauge Length Selection – 10, 25, 50 mm

- Lower force & higher force data entry in % of maximum load to calculate proof stress

Units

- Load – kN, Kg, N

- Stress – kN/mm², N/mm² (MPa), Kg/mm²

- Displacement – mm

- Before starting the test, you will get all information entered regarding the test

- Fully customized header & footer information for test report

- Facilities to search, open, view, delete previously tested files

Results Parameters

Ultimate Load, Ultimate Strength, Displacement at Ultimate Load, Maximum Displacement, %Elongation, %Reduction in area, Breaking Load, Breaking Stress, Yield Load, Yield Strength, 0.02% Proof Strength, 0.1% Proof Strength, 0.2% Proof Strength, 0.5% Proof Strength, 1% Proof Strength, all Proof loads, Young’s Modulus

Results

- Fully customized result window

- You can change all interfaces as per your requirement like color, font, etc.

- Two graphs in results (If Extensometer is used)

- You can see the graph of Stress Vs Displacement, Stress vs. %Strain (Piston defln), Stress vs. Strain (Piston defln)

- You can change curve color

You can mark the following points on the curve

- Ultimate Load

- Yield Load

- Displacement at Ultimate Load

- Displacement at Yield Load

- Proof Load

You can set the graph grid as per your requirement

- Complete curve zoom facility

- You can magnify a selected portion of the curve

- You can see all data points in tabular format such as Load – Displacement, Stress – %Strain

- Datapoint stressing facility in two ways – By moving the mouse on the curve or by arrow key

- You can Export Data to Excel

- On-line / Off-line buttons to start real-time data recording & to show real-time graphs

- Tare Load button in software so you can tare load of electronic Panel

- Reset Displacement button in software so you can reset displacement of electronic panel

- Reset Extension button in software so you can reset extension of electronic panel

- Fully Customized Test Report

Optional Features

- Test Type…

- We can develop test as per your requirement

Real-time Graphs

- As per your requirement

- Time graphs against any parameter (Load / Displacement / Strain / Extension etc)

Specimen Types

If you have any new type of specimen we can customize our software as per your requirement like Hex Bar etc

Optional Features

- Test Type…

- We can develop test as per your requirement

- Real-time Graphs

- As per your requirement

- Time graphs against any parameter (Load / Displacement / Strain / Extension etc)

- Specimen Types

- If you have any new type of specimen we can customize our software as per your requirement like Hex Bar etc

Units

- Load – as per your required unit

- Stress – as per your required unit

- Displacement – as per your required unit

Results Parameters

As per your requirement

Batch Report as per your format

Customized Test Report as per your requirement

Statistical Analysis

Hysteresis Tests

Torsion Tests

Spring Tests (Modulus of Data)

Test Certificate as per your format

Electronic Features – Universal Testing Machine

- Microprocessor-based Electronic Control Panel

- Full fledge membrane keyboard

- Data entry for specimen dimensions

- Scrolling of test results data up to breakage

- Results include Load Vs Displacement curve, Max Load, UTS, %Elongation, %Reduction in Area

- Aesthetic look, Siemens – Grey colored Power coated panel.

- Rotary Encoder for piston movement measurement. (Resolution 0.1mm)

- Pressure Transducers to measure Hydraulic Pressure

Technical Details

| Model | ME-UTE 10 | ME-UTE 20 | ME-UTE 40 | ME-UTE 60 | ME-UTE 100 | |

| Maximum Capacity | kN | 100 | 200 | 400 | 600 | 1000 |

| Measuring Range | kN | 0-100 | 0-200 | 0-400 | 0-600 | 0-1000 |

| Load Resolution | N | 5 | 10 | 20 | 30 | 50 |

| Load Rage with Accuracy +/-1% | kN | 2 to 100 | 4 to 200 | 8 to 400 | 12 to 600 | 20 to 1000 |

| Displacement Resolution | mm | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Clearance for tensile at fully descended working piston | mm | 50-700 | 50-700 | 50-700 | 50-800 | 50-850 |

| Clearance for compression test at fully descended working piston | mm | 0-700 | 0-700 | 0-700 | 0-800 | 0-850 |

| Clearance between columns | mm | 500 | 500 | 500 | 600 | 750 |

| Ram stroke | mm | 150 | 200 | 200 | 250 | 250 |

| Straining/piston speeds (at no load) | mm/min | 0-300 | 0-150 | 0-150 | 0-100 | 0-80 |

| HP | – | 1.3 | 1.3 | 2.3 | 2.5 | 3.5 |

| V | – | 400-440 | 400-440 | 400-440 | 400-440 | 400-440 |

| Æ | – | 3 | 3 | 3 | 3 | 3 |

| Weight approx. | kg | 1500 | 1500 | 2500 | 3500 | 5500 |

| DIMENSIONS | ||||||

| L X W X H (approx.) | mm | 2032 x 750 x 1960 x |

2032 x 750 x 1960 x |

2060 x 750 x 2180 x |

2065 x 750 x 2534 x |

2415 x 815 x 2900 x |

STANDARD ACCESSORIES

| Model | ME-UTE 10 | ME-UTE 20 | ME-UTE 40 | ME-UTE 60 | ME-UTE 100 | |

| FOR TENSION TEST | ||||||

| Clamping jaws for RoundSpecimens of Diameter | mm | 10-20 20-30 |

10-20 20-30 |

10-25 25-40 |

10-25 25-40 |

10-25 25-45 |

| Clamping jaws for Flat Specimens of Thickness Width |

mm | 00-10 10-20 50 |

00-10 10-20 50 |

00-15 15-30 65 |

00-15 15-30 70 |

0-22 22-44 70 |

| FOR COMPRESSION TEST | ||||||

| Pair of Compression Plates of Diameter | mm | 120 | 120 | 120 | 120 | 160 |

| FOR TRANSVERSE TEST | ||||||

| Table with adjustable rollers width of rollers | mm | 160 | 160 | 160 | 160 | 160 |

| Diameter of rollers | mm | 30 | 30 | 30 | 50 | 50 |

| Maximum clearance between supports | mm | 500 | 500 | 500 | 600 | 800 |

| Radius of punch tops | mm | 6,12 | 6,12 | 12, 16 | 16, 22 | 16, 22 |