- Ichalkaranji, Kolhapur, Maharashtra

- GST NO. : 27AZRPK7585N2Z5

- +91-9766667892, +91-9823292327

Hardness Testing Machine

Leading Manufacturers, Exporters, Wholesaler of ME-B-3000(H) Brinell Hardness Testing Machine, ME-B-3000(J) Brinell Hardness Testing Machine, ME-B-3000(O) Brinell Hardness Testing Machine, ME-B-3000(PC) Brinell Hardness Testing Machine, ME-RAS Rockwell Hardness Testing Machine, ME-VM-50 PC Vickers Hardness Testing Machine, ME-VM-50 Vickers Hardness Testing Machine and Rockwell Cum Brinell Hardness Testing Machine from Kolhapur.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loads | 500 to 3000 in stages of 250 kgf |

| Initial Load | 250 kgf |

| Max. Testing Height | 410 MM |

| Depth of Throat | 200 MM |

| Max. Depth of elevating screw below the base | 180 MM |

| Size of Base | Size of Base MM |

| Machine Height | 1127 MM |

| Net Weight (Approx.) | 450 kg. |

| Drive Motor | 0.33 – 415 V/P HP |

Preferred Buyer From

| Location | Worldwide |

Mechatronic Engineers Testers Model ME-B-3000(H) is precision-engineered to IS:2281- 1968, BS:240 and ASTM: E10. However, ME-B-3000(H) is most suitable for production testing. These machines are designed to measure the hardness of casting, forgings, other metals and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loads | 500 to 3000 in stages of 250 kgf |

| Initial Load | NIL kgf |

| Max. Testing Height | 254 mm |

| Depth of Throat | 150 mm |

| Max. Depth of Elevating Screw Below the Base | 0 Mm |

| Size of Base | 255 X 495 mm |

| Machine Height | 860 mm |

| Net Weight (Approx.) | 250 kg |

| Drive Motor | NIL HP |

Preferred Buyer From

| Location | Worldwide |

Mechatronic Engineers Testers Model ME-B-3000(J) is precision-engineered to IS:2281- 1968, BS:240 and ASTM: E10. However, ME-B-3000(J) is most suitable for production testing. These machines are designed to measure the hardness of casting, forgings, other metals and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loads | 500 to 3000 in stages of 250 kgf |

| Initial Load | Nil kgf |

| Max. Testing Height | 380 MM |

| Depth of Throat | 200 MM |

| Max. Depth of elevating screw below the base | 180 MM |

| Size of Base | 370×670 MM |

| Machine Height | 1185 MM |

| Net Weight (Approx.) | 500 kg |

| Drive Motor | 0.33-415v/p HP |

Preferred Buyer From

| Location | Worldwide |

Mechatronic Engineers make Hardness Testers Model ME-B-3000(O) is precision-engineered to IS:2281- 1968, BS:240, and ASTM: E10. However, ME-B-3000 (O) is most suitable for production testing. This machine is designed to measure the hardness of casting, forgings, other metals, and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loads | 500 to 3000 in stages of 250 kgf |

| Initial Load | Nil kgf |

| Max. Testing Height | 380 MM |

| Depth of Throat | 200 MM |

| Max. Depth of elevating screw below the base | 180 MM |

| Size of Base | 370×670 MM |

| Machine Height | 1185 MM |

| Net Weight (Approx.) | 500 kg. |

| Drive Motor | 0.33-415v/p HP |

Preferred Buyer From

| Location | Worldwide |

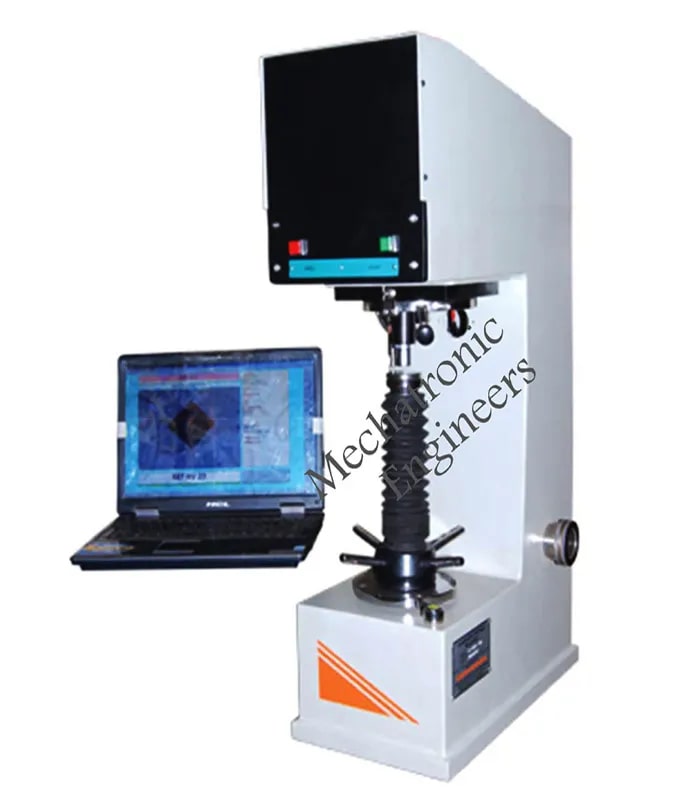

Mechatronic Engineers make Hardness Testers Model B-3000(O) is precision-engineered to IS:2281- 1968, BS:240, and ASTM: E10. However, ME-B-3000 (O)PC is most suitable for production testing. This machine is designed to measure the hardness of casting, forgings, other metals, and alloys of all kinds, hard or soft, whether flat, round or irregular in shape.

Available Models:

- Regular Computerized Machine

- Semi-automatic operation

- Fully Automatic Machine means loading/unloading and results will get automatically.

The software:

- Facility for Auto/semi Auto / Manual modes of operation.

- Well managed database saves readings w.r.t. batch.

- Facility for calibration and check of calibration.

Applications :

- To measure Rockwell Hardness directly on machine where presently Rockwell-Microscope is used. This avoids eye-straining of the operator on producing testing. In addition, it gives far better-repeated accuracy. High-low limits selections enables operator easy acceptance/rejection of components.

- Can be connected to a Laptop or Desktop PC. Easy to carry anywhere and handy for use with easy setup.

Scope of Supply

- Machine containing CCD Camera, optics, and illumination systems with connecting cable.

- External Video capture with USB 2 connectivity and driver software.

- Rockwell Impression Measurement System (B.I.M.S.) software.

- PC or LAPTOP and windows XP operating systems is to be procured by the customer.

- One USB 2.0 and one RS232 (serial) interface (9 pins) is required and it is recommended for the Laptop to use an external USB to serial converter for the RS232 interface.

Calibration Facility

The systems include calibration and check facilities to calibrate the systems and for checking of calibration. This eliminates any system error in measurement.

The range of Measurement is from 1 mm to 6 mm of diameter with a Resolution of 0.01 mm.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loads | 60, 100 & 150 kgf |

| Initial Load | 10 kgf |

| Max. Testing Height | 230 mm |

| Depth of Throat | 200 mm |

| Max. Depth of elevating | 240 mm |

| Size of Base | 171 x 423 mm |

| Machine Height | 635 mm |

| Net Weight (Approx.) | 75 kg. |

| Drive Motor | 0.33-415v/p HP |

Preferred Buyer From

| Location | Worldwide |

Model ME-RAS Digital

- Digital Hardness Tester for Rockwell tests. Motorized for automatic operation cycle i.e. load / dwell / unload.

- Preliminary Test Force – 98.07N (10 kgf.)

- Additional Test Force – 490.3, 882.6, 1373N (50, 90, 140 kgf.)

- Total Test Force – 588.4, 980.7, 1471N (60, 100, 150 kgf.)

- Test Force selection by external dialing.

- Set position with LED bar indicator for easy operation.

- Keyboard entry through reliable membrane switches for scale / GO-NOGO / dwell time selection.

- Large size scale display for easy reading with 0.1 Rockwell resolution.

- Parallel output for connecting dot matrix printer to get results indicating a serial number of tests, hardness scales, hardness value, and high/good / low indication.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Test Loads | 5, 10, 20, 30, 50 kg. (Optional 1 Kg) |

| Max. Test Height (mm.) | 200 |

| Diagonal measuring range (mm) | 0.05 to 0.4 |

| Scale least count(mm.) | 0.001 |

| Depth of throat (mm.) | 133 |

| Dimensions of Machine (mm.) | L585 x W290 x H860 |

| Weight (Approx) | 73 kg. |

| Power Supply | 220V AC, 50 Hz, 1-Phase |

Preferred Buyer From

| Location | Worldwide |

Features

- Fully Computerized (PC Based) Vickers Hardness Machine.

- Direct and accurate measurement of Vickers Hardness Number using “State of Art” image processing technology.

- ‘Wide testing range: from soft metal such as the lead up to medium hardened steels.

- High accuracy and repeatability of measurement at all loads.

- Faster measurement yielding to higher productivity.

- The small size of indentation makes non-destructive testing on finished components.

- Motorized loading and unloading cycle.

- Small loads allow the testing of thin sheet metals.

- Advanced Window XP based software.

Latest GUI Features:

- User-friendly software with all help files and Window Features.

- Online indentation setting and focusing on the PC monitor.

- Advance image processing Algorithms implemented for a precise calculation of hardness numbers with various options to cover all ranges of specimens.

Batch file Processing :

Option for data/storage and reports generation.

Statistical Evaluation:

Software for calculating standard deviation, mode medium, histogram, etc.

Options in calibration mode:

Calibration / Verification on PC monitor makes it easier to operate.

Computerized Vickers Hardness Tester is a simple and accurate means to produce automatically measure the diamond indentation to give Vickers hardness numbers. These testers are suitable for measuring the hardness of precision metallic parts with a wide testing range – from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS 1754 – 2002.

Construction

To accommodate the high precision loading system & an optical projection screen, the machine frame is designed sturdy. The specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied to a diamond penetrator by means of a lever & weights. The load is removed automatically after a specific lapse of time. The objective is indexed with the test piece & the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Test Loads | 5,10,20,30,50kg. |

| Magnification of optical projection | 70X |

| Max. Test Height (mm.) | 200 |

| Scale least count(mm.) | 0.001 |

| Depth of throat (mm.) | 133 |

| Dimensions of Machine (mm.) | L585xW290xH860 |

| Weight (Approx) | 73kg. |

| Power Supply | 220V AC, 50 Hz, 1-Phase |

Preferred Buyer From

| Location | Worldwide |

Features

- Tiny indentation allows the testing of precision finished parts.

- The thin sheet metal is perfectly tested. Because the applied load is very small.

- Motorized loading and unloading cycle.

- Built-in projection screen to get accurate results.

- The same hardness number is obtained on the same specimen, regardless of the load applied.

- Wide testing range, from a soft metal such as lead, Upto the hardest, like hardened steel.

Construction

To accommodate the high precision loading system & an optical projection screen, the machine frame is designed sturdy. The specimen is placed on a testing table. The test cycle is fully automatic. The accurate load is applied to a diamond penetrator by means of a lever & weights. The load is removed automatically after a specific lapse of time. The objective is indexed with the test piece & the diamond indentation is projected on the measuring screen. The diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Loads | 60, 100 & 150, 187.5, 250 kgf |

| Initial Load | 10 kgf |

| Max. Testing Height | 230 mm |

| Depth of Throat | 130 mm |

| Max. Depth of elevating | 240 mm |

| Size of Base | 171 x 423 mm |

| Machine Height | 635 mm |

| Net Weight (Approx.) | 75 kg. |

| Drive Motor | 0.33-415v/p HP |

Preferred Buyer From

| Location | Worldwide |

MODEL : ME-RABI-250 Automatic load selection with automatic zero setting dial gauge. Manual Operation.

- Preliminary Test Force – 10 kgf

- Test Loads for Rockwell – 60, 100, 150 kgf

- Test Loads for Brinell – 187.5, 250 kgf

- Test Force selection by external dialing.